Wellsite XRF sample collection and analysis

X-ray fluorescence (XRF) is a non-destructive analytical technique used to determine the elemental composition of materials. In the context of oil and gas drilling, XRF offers several benefits:

- Elemental Analysis: XRF allows for rapid and precise identification of a wide range of elements in geological samples, drilling mud, and other materials used in oil and gas operations. This helps in understanding the composition of rock formations, identifying mineral content, and assessing drilling conditions.

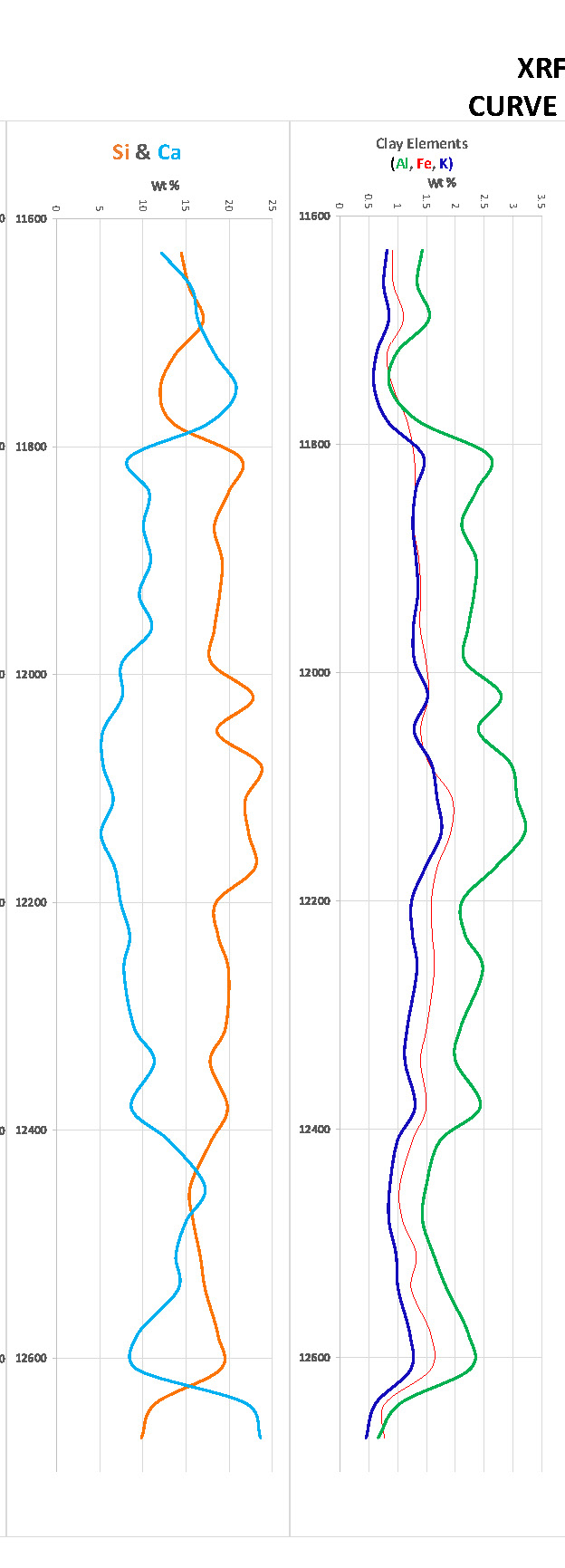

- Geochemical Logging: XRF can be used to create geochemical logs that track the changes in elemental composition throughout a drilling operation. This information is valuable for correlating different layers of rock and identifying key geological features, aiding in well planning and reservoir characterization.

- Environmental Monitoring: XRF can help detect and quantify potentially hazardous elements, such as heavy metals, in drilling mud and produced fluids. This is crucial for environmental compliance and monitoring to ensure that drilling operations do not pose environmental risks.

- Quality Control: In oil and gas drilling, it’s important to ensure that materials such as drilling muds and cement meet specific standards. XRF allows for quick quality control by analyzing the elemental composition of these materials, ensuring that they contain the correct proportions of key components.

- Operational Efficiency: XRF provides real-time or near-real-time results, allowing for quicker decision-making during drilling operations. This can help optimize drilling processes, reduce downtime, and improve overall efficiency.

- Cost Reduction: By identifying potential issues early, XRF can help reduce costs associated with drilling delays, unexpected problems, and remediation. It also reduces the need for costly and time-consuming traditional chemical analysis.

- Safety: XRF is a non-destructive method, minimizing the need for extensive sample preparation or handling of hazardous chemicals. This contributes to safer working conditions on-site.