In the fast-paced world of unconventional drilling, the difference between hitting the target zone and overshooting it can come down to decisions made in minutes — not days. That’s why near real-time elemental analysis using X-ray fluorescence (XRF) is becoming a must-have at the wellsite. When interpreted by experienced geologists, XRF data provides powerful insights into lithology, mineralogy, and reservoir quality — all without waiting for lab results.

At Field Geo Services, we bring portable, high-resolution XRF technology to the rig, coupled with expert interpretation, so operators can make smarter decisions right when it counts.

What Is XRF and Why Does It Matter?

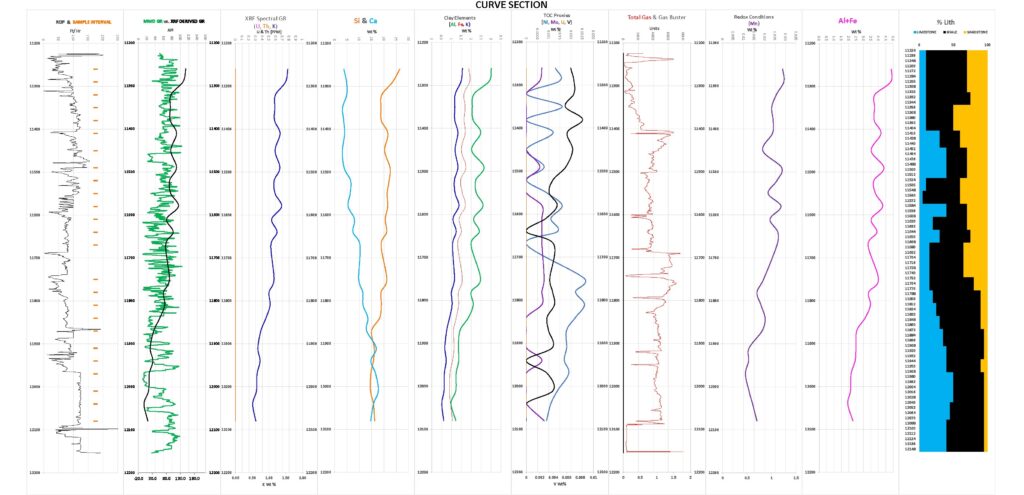

XRF is a non-destructive analytical technique that measures elemental concentrations in rock cuttings and core samples. From a small chip of shale or sandstone, we can derive concentrations of major elements (like Si, Ca, Fe, Al) and trace elements (like V, Ni, U, Sr) in real time. These values are then interpreted to:

- Identify formation tops and changes in lithofacies

- Map mineralogical trends (e.g., carbonate vs. silicate content)

- Evaluate proxies for Total Organic Carbon (TOC) and redox conditions

- Determine mechanical properties like brittleness for frac design

Why Interpretation Is Key

Like any dataset, raw XRF numbers only tell part of the story. Expert interpretation turns those numbers into geological narratives. For example:

- Elemental Ratios (e.g., Si/K, Fe/Al, Ti/Zr) help correlate chemostratigraphic packages, even where lithologic descriptions fall short.

- Brittleness Proxies (e.g., Si + Ca + Mg) can indicate zones more likely to fracture effectively.

- TOC Indicators (e.g., elevated U, V/Cr) guide operators to richer source rock intervals.

At FGS, we apply proprietary interpretive models and we tailor them to the geology at hand.

Real-Time Value, Real-World Impact

By integrating XRF with mass spectrometry, mudlogging, and LWD data, FGS gives you a multidimensional view of the wellbore. Some examples of XRF’s impact at the wellsite include:

✅ Geosteering through subtle formation changes in the Permian using chemostratigraphy

✅ Avoiding carbonate stringers that reduce frac efficiency

✅ Real-time feedback on TOC trends to target more productive intervals

✅ Post-well reporting that supports landing zone optimization for future wells

FGS Delivers More Than Just Data

Our wellsite geologists are trained in the collection of XRF data and our geochemistry team are experts in interpreting and analyzing XRF data. That means no delays, no guesswork, and no missed opportunities. Whether you’re drilling in the Bakken, Eagle Ford, Powder River or Permian, FGS brings unmatched geological expertise and operational know-how to every job.

Bottom Line: When used correctly, XRF doesn’t just tell you what’s in the rock — it tells you where to drill, how to frac, and how to maximize your reservoir contact.

Want to put real-time XRF interpretation to work on your next well?

Contact us today at sales@fieldgeoservices.com to request a bid or schedule a technical consultation.

[…] spectrometry and XRF provide high-resolution elements in the rock from drill cuttings and chemistry in the gas stream while drilling. These tools give operators the […]

[…] cuttings themselves haven’t changed, but what we can do with them has. X-ray fluorescence (XRF) and mass spectrometry (MS) have made it possible to extract a wealth of elemental and […]